GKG G5 Full Auto SMT Stencil Printer 60HZ 3KW Paste Printer

Machine

GKG G5, GKG full auto printer

Product features of GKG G5 automatic solder paste printing machine:

1. GKG dedicated manual adjustment jacking platform

Simple structure, low cost, and convenient manual adjustment, which

can quickly adjust the lifting height of PIN needles of PCB boards

of different thicknesses

2. Image and light path system

The new optical path system-uniform ring and high-brightness

coaxial light, coupled with the brightness function that can be

adjusted steplessly, makes all types of Mark points can be well

identified (including uneven MARK points), suitable for plating

Tin, copper-plated, gold-plated, tinned, FPC and other types of

PCBs with different colors

3. Scraper system

Sliding rail type scraper system to improve operation stability and

prolong service life

4. Cleaning system

The new type of wiping tape ensures full contact with the steel

mesh, and the enlarged vacuum suction force ensures that the

residual solder paste in the mesh is eliminated, and the effective

automatic cleaning function is truly realized; dry and wet vacuum

three cleaning modes, software can be set at will Cleaning mode and

length of cleaning paper

5. Stable steel mesh fixed structure

6. Complete 2D inspection system

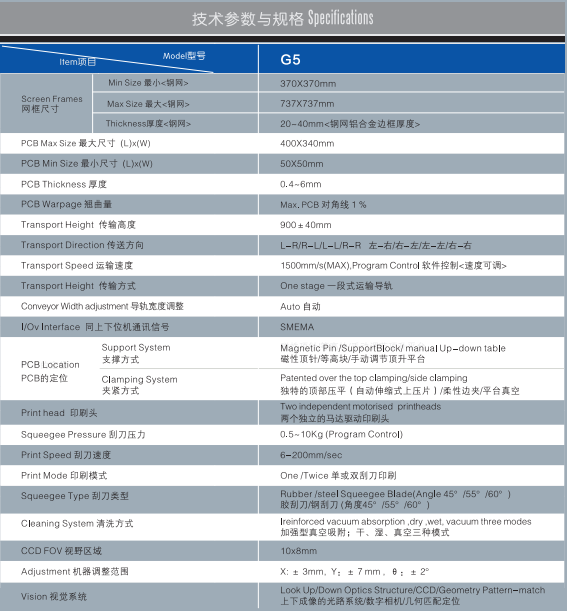

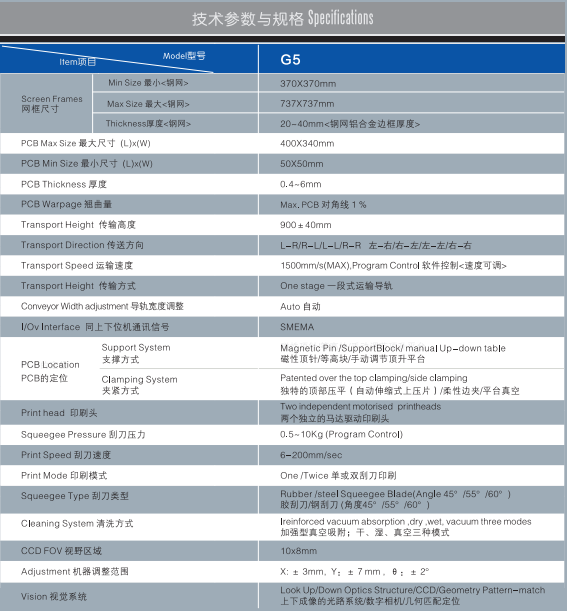

GKG automatic solder paste printer G5 specifications:

Device model: G5

Screen frame size: 420×520mm~737×737mm

Large PCB size: 400×310mm

Small PCB size: 50×50mm

PCB thickness: 0.4-6mm

PCB warpage: Max.PCB diagonal 1%

Transmission height: 900±40mm

Transmission direction: Left-Right Right-Left Right-Right Left-Left

Transport speed: 1500mm/s(MAX), Program Control

Conveying method: one-stage transport track

PCB positioning and support method: magnetic needle

top/automatically adjustable jacking platform Tight clamping

method: unique top flattening upper plate, side clamp

Print head: Two independent motors drive the print head

Scraper pressure: 0-10kg (Program Control)

Cleaning method: enhanced vacuum adsorption, three modes of dry,

wet and vacuum

Field of view: 10.24×6.4mm

X, Y, θ adjustment: X, Y: ±8mm, θ: ±2° (increment 0.5micro)

Vision system: software processing/up and down simultaneous imaging

optical path system/1394 digital camera/geometric matching

positioning

Repeat positioning accuracy: ±0.01mm

Printing accuracy: ±0.025mm

Printing cycle: ≤8.5S

Changing time: 3mins for the old program, set up 5mins for the new

program.

Main air supply source: 4-6kg/cm2

Main power supply: AC: 220±10%, 50/60HZ 3KW

Control method: PC Control

Operating system: windows XP

Machine dimensions: 1210×1530×1510mm (machine body)

Total machine capacity: 1000kg

1. Purpose._

Properly operate the fully automatic E printing machine to ensure

the normal operation of the machine, thereby ensuring the product.

2 Applicable scope

Manufacturing department production workshop SMT

3 noun explanation

Solder paste printer: Modern solder paste printers are generally

composed of boards, adding solder paste, embossing, and

transferring circuit boards. Its working principle is: first fix

the circuit board to be printed on the printing positioning table,

and then the solder paste or red glue is printed on the

corresponding pad through the stencil by the front and rear

scrapers of the printer, and the printed PCB is transmitted through

Input to the placement machine for automatic placement.

4 responsibilities

4.1-The equipment engineer is responsible for the maintenance and

periodic maintenance of the printing press.

4.2 The equipment technician is responsible for the production and

modification of the printing press program.

4.3 The operator is responsible for the operation and maintenance

of the printing press.

4.4 The production supervisor is responsible for supervising the

execution.

5 Management Regulations

5.1 Check before starting

5.1.1 Confirm that the appearance of the machine is clean, and

confirm whether there is any debris inside the equipment,

especially within the operating range of the motion track.

5.1.2 Confirm that the working environment temperature is between

23±5℃: Humidity <80%

5.1.3 Make sure that the working air pressure of the equipment is

between 0.4 and 0.6 Ma.

5.1.4 Confirm that the equipment power supply and related

connecting wires are normal.

5.2 Boot

5.2.1 Turn on the power of the device. Figure 1. Device power

5.2.2 After the device is turned on, enter the reset interface,

[Start reset]; wait for the reset to complete. Figure 2. Device

reset interface Figure 3. Device reset completion interface

5.3 Calling the production program

5.3.1 Select the program authority according to the system prompts,

the operator does not need to enter a password, and the rest need

to enter the corresponding password to obtain the authority. Return

when finished.

Figure 4. Permission selection interface

5.3.2 In the main interface [Open Project] option, select the

corresponding production program

5.3.3 After the selection is completed, it will automatically

return to the main interface, and the program has been opened at

this time. [Data Entry]; Confirm the printing parameters of the

product to be produced.

5.4 Install steel mesh

5.4.1 After confirming the step data, the next step is to enter the

page, and the printer prompts to adjust the track width. Before

adjusting the width, confirm whether there is a top plate/thimble

on the platform, take it out if there is, and reinstall it after

the width adjustment is completed. The top plate should be

installed as close to the track as possible, between 1-2LCM from

the track but not in contact with the track, to prevent the track

from being worn and deformed. If you need to install the thimble,

you should avoid the bottom components to prevent collisions.

[Automatic positioning] option, at this time the printer will move

the ccD lens and set the entry baffle.

5.4.2 Feed the FCB from the exit of the printing machine. The

printing press will complete automatic positioning. At this time,

the PCB should be about 0.5mm higher than the track.

5.4.3 According to the type of machine to be produced, select the

steel mesh with the corresponding number "such as ECLG4A-V05). Then

select [Z-axis up], put the stencil into the frame support plate

and clamp it. Adjust the position of the B pad and the stencil

opening. The Y direction can be fine-tuned by the device. The X

direction is fine-tuned manually. After the adjustment is completed

[Fixed Valve of Screen Frame] and confirm that the steel mesh has

been clamped. [OK], complete the steel mesh installation.

Figure 12. Steel mesh installation

5.5 Specially installed scraper, adding solder paste

5.5.1 Place the two scrapers on the scraper seat and lock them

tightly. Shake the scraper gently with your hand to confirm the

installation effect.

5.5.2 The [Print from Back] button at the top of the main interface

moves the squeegee backwards, and adds the thawed solder paste to

the stencil. The width of the solder paste should be slightly

larger than the width of the opening of the stencil and smaller

than the width of the squeegee. Missing printing occurs. [Print

from front] button at the top of the main interface, move the

scraper to the front of the tin sound.

5.6 Printing effect inspection

5.6.1 [Start] button on the right side of the main interface,

follow the prompts to transfer the PCB on the track and re-inject

the new FCB, the device will automatically align the stencil

according to the previous set value, and prompt for device

fine-tuning before printing. 5.6.2 The device fine-tuning method is

that the Z-axis platform drives FCE to perform four-way

fine-tuning. Move FCB in the left and up direction [+], right and

down direction is [-.

5.6.3 [Confirm] after debugging, the equipment will print

automatically. Manually check the printing effect after the

printing is completed. If it is qualified, the interface will be

fine-tuned before the next printing, and it will enter the

automatic printing mode. If it is unqualified, the fine-tune will

be repeated until it is qualified.

SMT SONY Stick feeder

SMT Stick feeder, yamaha stick feeder, yamaha yv100x stick feeder,

yamaha ys12 ys24 stick feeder,yamaha vibrator feeder

JUKI Stick feeder, samsung stick feeder,fuji nxt stick feeder,

stick feeder,

PCB storage, pcb trolley, pcb rack,pcb hanging cart,

Solder paste warm up machine, digital smt solder paste recovery

machine,

Company Information

CNSMT is the leading manufacturer and supplieir for SMT machines

and Solution with over 10 years' experience in China. And we can

also do OEM&ODM for SMT traders, we have vast of sources in SMT

field,even you need used or new SMT equipments or other parts, we

can help you get the best quality and competitive cost machines.

What we can do for you:

※ We have our own factory make SMT equipments and devices

※ We have a professional technich engineer team for produce

machines

※ We can customize variety of SMT machines for you according your

requirements

※ We buy and sell used and new SMT equipments all over the world

※ We provide you SMT full line machines and export to worldwide

※ Becoming the most reliable Chinese partner for you.

FAQ:

1. Are you factory?

Yes, we are factory supplier focus on humidity control for 14

years.

2. Can you email the catalog?

Yes, we can send you by email with whole catalog.

3. How to order online?

Confirm product (quantity, price, payment, shipping etc)---waiting

for email ---confirm order---make initial payment---production

finish---make balance payment---shipping

* click to learn about trade assurance

4. What about the payment way?

30% deposit, balance paid before delivery -- amount > USD5,000

100% deposit -- amount < USD5,000

5. What's the shipping way and timing?

We suggest to ship by sea to get cheapest rate, voyage date to

America around 30~40 days, to Europe 25~30 days, to Asia and

Austrilia 7~15 days. Click here to get exact timing.

6. What's the warranty item?

Warranty time normally is 12 months, if you want to extend the

warranty time to 24 months, the value will be 10% more of your

order.

7. Can I visit your factory?

Yes sure, welcome to visit our factory to get more profit.

8. How to contact with your factory?

Send inquiry in below form or send mail or call to select your way.

Click here

9. Can you customize the product?

Yes, we can customize any products according to customer's

requirements.

10. Which payment terms are you doing?

PayPal, West Union, T/T, (100% payment in advance.)

11. Which shipment is available?

By sea, by air ,by express or as your requirement.

12. Which country you have been exported?

We have been exported to many countries, all most all around the

world, like Malaysia, Vietnam, Thailand, United States, France,

Spain, Mexico, Dubai, Japan, Korea, Germany, Porland Etc.